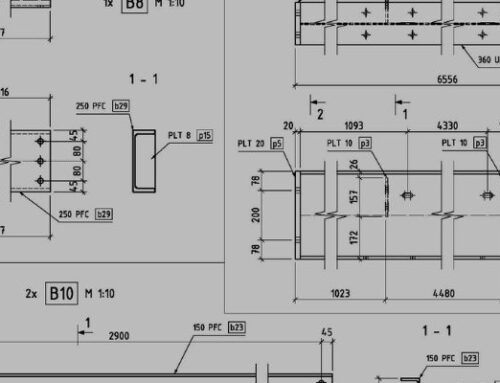

A spool is a short section of pipe used to connect two larger pipe sections in a pipeline system. Spool fabrication drawings are detailed technical drawings that provide fabricators with the necessary information about the dimensions, materials, and fabrication to create each spool. It is also involved in the production of a customized piping system that is assembled from a number of individual components, including pipes, fittings, and valves. The spool fabrication drawing may also include essential information about the flanges, gaskets, bolts, and other components required to attach the spool to the pipeline during the design phase of a pipeline project. The designers and engineers create detailed plans for the various pipeline segments to guide the fabricators at the time of fabrication of spools for pipeline projects.

Spool fabrication drawings :

The spool fabrication drawings are created by using specialized software. The engineers or designers use advanced software to create 3D models of pipeline spools, which can be viewed from any angle. The use of software in the spool drawings allows the engineers and manufacturers to install the fabrication of each spool. The process of spool fabrication involves several steps, including design, cutting, shaping, and welding. It also aids in creating precise and accurate models of the spools to create complex requirements of the pipeline projects.

Importance of accurate spool fabrication drawings:

The accurate spool drawings play an important role in the process of fabrication of pipelines at the time of construction.

Accurate and Precise spool fabrication:

Accurate and precise fabrication of the pipelines ensures that each spool is manufactured to the exact dimensions with the required specifications. This involves in the use of specialized machinery and equipment. The fabricators review this pipe spool drawing and follow the instruction for each spool in the construction process. It also ensures that the pipelines of the spools are erected efficiently and effectively. The accurate and precise fabrication drawings offer various advantages such as,

Improved workflow:

The spool fabrication significantly increases the workflow in the process the fabrication. The use of digital tools and software also improves efficiency in spool fabrication. The usage of 3D modelling services and simulation software can help engineers and designers to optimize designs before they are fabricated. It aids in reducing the risk of errors and rework. Improving efficiency in spool fabrication requires a combination of advanced technologies, streamlining workflows, digital tools and software, and skilled labour.

Improved cost-effectiveness:

Accurate spool fabrication drawings help to streamline the fabrication process by providing detailed instructions to the fabrication team. This helps to reduce the risk of accidents or other safety issues that could result in additional costs.

Quality control and safety:

The quality control includes the visual inspection of each pipe segment. It involves in tracking detailed records of each step in the manufacturing process and also in the installation of pipe spool fabrication for the fabricators.