Structural steel detailing is the process of detailed models and drawings of steel structures. The fabricators and constructors use these detailed drawings to elevate the steel members for easy fabrication in the construction industry. It creates detailed drawings of individual parts, such as beams, columns, and other steel components. These structural drawings of the steel structure are created by a 3D model using specialised software. The steel detailer precise all necessary information and specifications for the fabrication process using Tekla structures, SDS/2 and advance steel.

3D Modeling in Structural Steel Detailing

3D modelling is a digital representation of a fabrication structure in three dimensions. The significant benefit of using 3D modelling in steel structure improves accuracy and efficiency in the process of construction. The transition towards 3D steel detailing offers various benefits in the different stages of steel fabrication.

The most prevailing 3D modelling software used in the structural steel fabrication industry are as follows,

Tekla Structures is a widely used 3D modelling software in the fabrication industry and offers accurate and detailed information about steel structures in the manufacturing process.

SDS/2 is commonly used for detailing, fabrication, and erection of steel structures. It aids in the automated designing process, including creating shop drawings, fabrication details, and CNC data.

Advance steel is specifically designed for steel detailing and fabrication, which offers greater flexibility and a wide range of customization. It also ensures better quality and increases streamlined workflow.

Benefits of using 3D Modelling in Structural Steel Detailing

Versatile visualisation:

The use of 3D modelling software enhances 3D visualisations for more efficient and effective collaboration. It enhances complex designs and ideas of steel structures more effectively. The steel detailer creates models with Tekla structures that are highly detailed and accurate. It allows designers and engineers to visualize and analyze the steel structure at the time of installation of steel members.

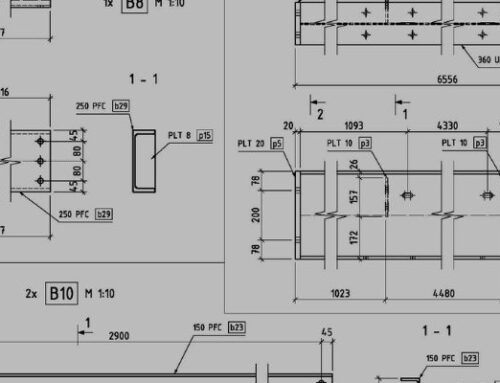

Precision Detailing:

The process of precision detailing involves accurate and detailed models of steel structures for construction projects. The primary objective of the structural steel detailer is to create precise, detailed drawings to meet the required standards and specifications. It also ensures that the drawings are easy to read and understand the plans and design for the fabricators in the process of construction. It increases the efficiency of structural steel detailing throughout the construction.

Effective collaboration:

The steel drafting services augment effective communication to understand the project’s scope, requirements, and expectations by the fabricators and erectors at the time of installation of steel members. It intensifies the stipulation of ideas, plans and designs to the fabrication’s engineers, architects and contractors for easy fabrication.

Review and Revise:

The advanced software specification induces accurate measurements and eliminates manual revision or rework to reduce the time for the revision process.

Minimising Errors:

The use of 3D models in steel detailing can significantly minimise potential errors. It stimulates the fabrication and erection process effectively. It professes the detailers to change the designs and plans before the erection. It improves the overall quality of the detailing process and reduces the cost of the project.