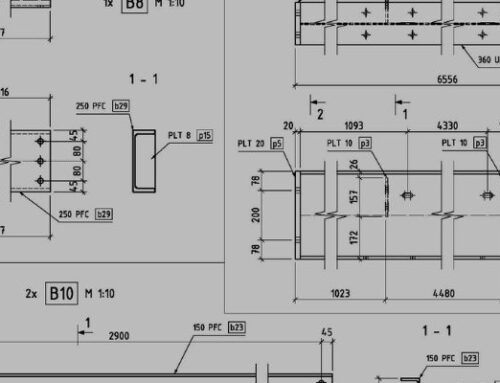

Steel detailing and drafting are the distinct processes that ensure detailed plans and specifications of high quality steel components structures and technical documentation. It assists as a necessary guide to the construction process. The detailed steel drawings and models impart basic information on the components of technical drawings. These steel detailing and drafting ensure exact shape, dimensions, connections, and materials required to construct a steel structure. The detailed drafting plans and specifications of construction documents aid in easy communication for construction professionals to fabricate steel members. The steel detailers and drafters adapt the latest trends and technology in fabricating detailed technical drawings for the erection of steel members. It improves work efficiency during construction projects in the commercial, residential and mechanical industries.

Steel Detailer And Drafter

The professional steel detailer and drafter offer various discrete advantages in detailing steel components. This adoption of technology in steel structures avails potential safety, enhanced collaboration, improved efficiency and accuracy. The design and fabricated components enhance the quality of work to meet the required standards. The detailed drawings represent the structural steel elements of the building or infrastructure projects.

Trends And Technologies In Steel Detailing And Drafting

The eminence of the latest trends and technologies that emerged in the field of steel detailing and drafting services are as follows,

Detailed 3D Modelling:

The prominent use of 3D modelling in steel detailing and drafting services allows detailed representation of steel structures. It creates versatile visuals of the steel structures, which can be viewed from any angle or direction. The primary benefit of 3D modelling in steel detailing is the ability to identify and resolve any contention before construction begins. The detailed shop drawings by the fabricators initiate the fabrication process and improve overall project efficiency. The indispensable role of 3D modelling services proffers the definite location and size of the individual steel components.

Building Information Modeling (BIM) in steel detailing:

Building Information Modeling (BIM) technology in steel detailing allows for a comprehensive 3D model of a building or structure. This digital technology of steel detailing and drafting furnishes and manages information on construction models for easy fabrication and erection. The purpose of detailing using the BIM model is being shared among the architects, engineers, contractors, and steel detailers to communicate and work collaboratively to reduce the risk of errors and delays during the construction process.

Laser Scanning in steel detailing:

Laser scanning is a technology used in steel detailing to capture data points and necessary information about an existing steel component and the overall geometry of the structure. It engages in retrofitting and renovation projects. The accurate measurements of existing steel structures ensure that the new steel components are fabricated to the correct specifications. It also aids in fixing excessive deflection and corroded steel components in the process of construction.

Nesting software in steel detailing:

Nesting software is commonly used in manufacturing and fabrication industries. These software tools use advanced algorithms to analyze, design and optimize the steel fabrication. It optimizes the placement of raw materials, labour and machines. It also generates a cutting plan that minimizes waste and increases precision in steel fabrication.

Cloud-Based Collaboration in steel drafting:

Cloud-based collaboration enables sharing of files and documents to speed up the drafting process. It acts as an extensive source of project transparency and reduces the risk of errors and inconsistencies in steel erection in the field of the construction process.