A spool is used in piping and other mechanical industries. It is a piece of piping that is cut, machined, and fitted with flanges, valves, and other components for a fabrication facility. The spools are referred to as the pre-fabricated section of piping. This pre-fabricated section of piping is designed for easy communication and understanding for quick installation and well connection towards the piping system. The spool drawings play an essential role in fitting the pipe structure with various detailed drafting of raw materials to be fixed during the process of piping systems in industries. The engineers or designers draft detailed structures of spool fabrication drawings by using software tools and adorn features for creating 2D and 3D drawings. These 2D or 3D modelling tools detailed the specific information on dimensions, materials and requirements for installation of the spool in the piping system. This makes engineers to determine the visual representation of the pipe spool and the optimal pipe size and material for the specific application. It facilitates the process of maintenance and repair of the piping system and improves the overall efficiency of the fabrication process, reducing downtime and increasing productivity.

Role Of Pipe Spool Fabrication Drawings

The pipe spool drawing provides detailed information on the proper interpretation and execution of the piping system. It ensures the fabricator’s control over the installation of pipe spools. These spool drawings help to improve communication and provide a clear set of specifications and requirements for the construction. It initiates the process by condensing the potential for misunderstandings or errors. It fends off the streamline of the construction process by reducing the cost and improving the overall quality of the piping system. It ensures safety, quality, and efficiency in the system’s construction, maintenance, and operation.

Various Roles Of Pipe Spool Fabrication Drawings

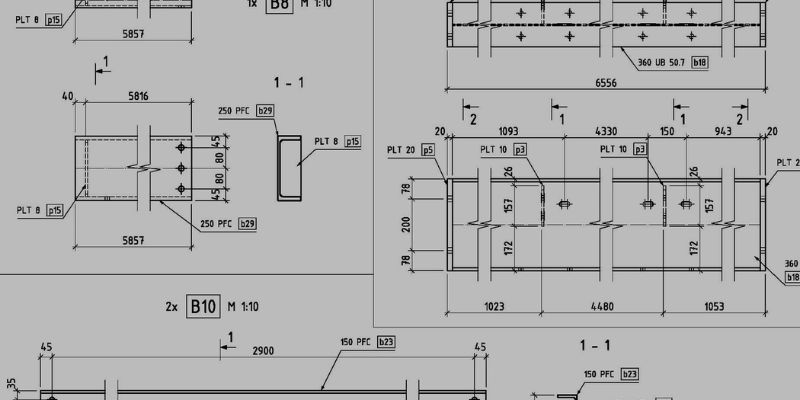

Pipe routing specifies the routing and layout of the piping and offsets or transitions between different pipe sizes or materials.

Fittings lay out the types and sizes of elbows, tees, reducers, and couplings used in pipe spools.

Flanges are used to fix each flange’s bolt patterns and gasket requirements.

Valves are of different shapes and sizes, including isolation, control, and relief valves to detail the piping system.

Supports features hangers, anchors, and guides to fix the support location.

Welding precisely the procedure and requirements at the exact point of the spool in piping.

These are the various functions and methods involved in the process of positioning the sequence of spools in the fabrication of the piping system.